Latest from Industry

Rep & NEMRA News

Rep News - December 20, 2024 Update

Rep News - December 6, 2024 Update

3Q 2024 Business Conditions & Latest Pricing Trends

AD-IMARK Finalize Merger

The market for process automation integrated into connected data networks on the plant floor has seen a surge of innovative offerings involving ideas like “digital twins” for modeling operating performance down to the device level. With a new solution introduced this week, Schneider Electric, Foxboro, MA, sees an opportunity to take that data into a new area: measuring profitability down to the device level in real time.

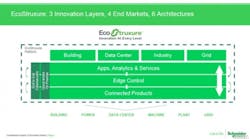

Developed through a partnership with Seeq, a Seattle-based provider of software and services that enable data-driven decision making for manufacturing and process operations, Schneider’s new EcoStruxure Profit Advisor uses “big data” analytics to measure the financial performance of an industrial operation in real time, from the equipment asset level of a plant up to the process unit, plant area, plant site and enterprise levels, Schneider said in a release. The system can be resident on-premises or in a cloud environment, where it mines both historical and real-time data and processes that data through a set of proprietary segment-specific accounting algorithms Schneider has developed to determine real-time operational profitability and potential savings.

“While many companies are getting really good at controlling the efficiency of their operations in real time, they’re still managing their business month-to-month. That just doesn’t work anymore,” said Peter Martin, vice president of innovation, Schneider Electric Process Automation. “Business variables are changing so quickly — sometimes by the minute — that by the time companies receive updates from whatever enterprise resource planning systems they use, the information is no longer relevant to the business decisions they need to make or should have made. If they want to change the game, they need to control their other real-time business variables, including their safety, their reliability and especially their operational profitability. Profit Advisor allows them to do that.”

Schneider says as current cost accounting systems only measure the financial performance of the industrial operation at the overall plant level, it is difficult for companies to truly understand the financial impact — positive and negative — operational changes have on business performance. To address that need, Profit Advisor allows plant personnel to see and understand the ROI and business value their actions, activities and assets are contributing to the business in real time. It empowers the workforce to make better business decisions with a variety of data analytics, which can be displayed in various formats, to help drive operational profitability improvements, safely.

Profit Advisor layers real-time accounting models onto the Seeq Workbench to create a scalable solution that can be integrated with Schneider Electric’s simulation and modeling software in a digital twin environment users can forecast profitability under different conditions or if changes to the operation are made.